Batch tracking and management for food with SAP Business One

To ensure that affected items can be quickly identified in the event of a recall or other quality issue, 100 percent traceability of ingredients is required by law in the food industry.

Digital batch management with SAP Business One enables easy, partially automated tracking of your batches. This saves you from manually capturing and logging batch information, which helps avoid errors and reduce your effort.

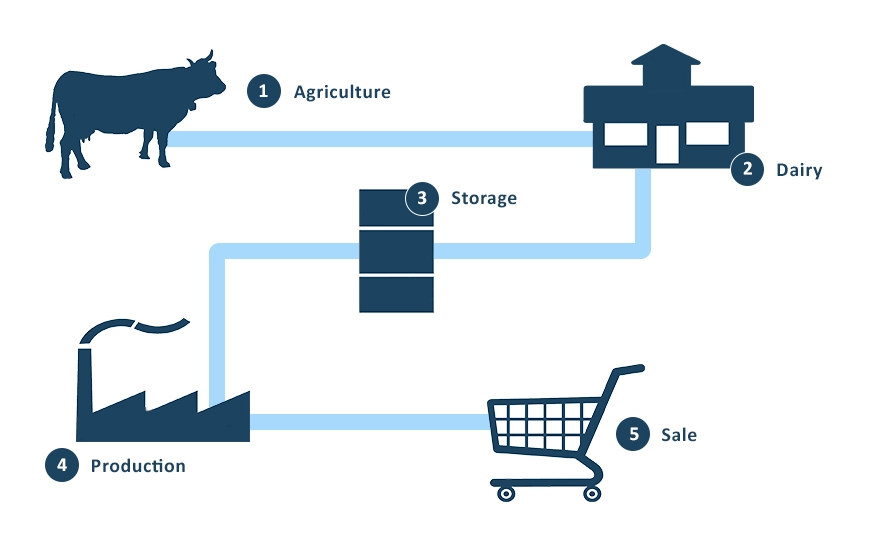

With the help of batch management for SAP Business One, you can keep track of your entire supply chain and individually trace the components of the delivered products.

Do you know this too? You reach your limits with ...

- the complete tracing of your goods

- the clear assignment of your goods to a batch

- accessibility to information about different batches

SAP Business One helps you solve these challenges. With the ERP software, you manage your batches in various ways:

- Batch generation: SAP Business One automatically generates batches from production orders. This ensures that each batch is uniquely identified and documented.

- Batch traceability: Once a batch number has been assigned, the batch can be tracked through the entire production process to delivery in real time. This enables rapid identification of affected batches and precise traceability in the event of problems and recalls. Thus, if manufacturing problems occur, only items belonging to the corresponding batch need to be recalled.

- Batch documentation: SAP Business One enables comprehensive documentation of batches, including delivery date, expiration date, and stock position. This ensures accurate recording and management of batches.

Advantages of batch management and tracing with SAP Business One at a glance

Digital batch tracking offers companies in the food industry decisive advantages. In particular, companies that work with different recipes or complex quantity ratios benefit from batch tracing using SAP Business One:

- Increasing the clarity and transparency of the manufacturing process

- Quality assurance of the products

- Compliance with legal requirements for the food industry

- Faster troubleshooting

- Reconstructable supply chains

How does batch management work with SAP Business One?

- As soon as raw materials arrive in the warehouse, the ERP system assigns a unique batch number and barcode to each material. When the barcode is scanned, the information about the material is captured and sent to the system.

- When a production order is placed, the ERP system assigns a batch number for the product to be produced. It checks the available resources in the warehouse and posts the raw materials from the corresponding material batch.

- Once production is complete, the path of the batch is tracked through the ERP system across the various stations and each movement is logged. Employees can retrieve the information on specific batches at any time by scanning the barcode.

Optimize your batch management with our performance boosters:

- With SIGMA Mobile Warehouse Management, you will realize your warehouse management paper-free in the future and retrieve data on batches and articles with a mobile handheld device simply by barcode scan.

- The SIGMA PDA terminal allows you to specify the batch to be used when starting production orders. A production order can also be started with the batch already specified.

What information does SAP Business One store about a batch?

FAQ - the most frequently asked questions about batch management with SAP Business One

A batch is a specific quantity of a product manufactured under the same conditions. The batch number, which is assigned by the manufacturer, serves to document the manufacturing process and the raw materials used. In this way, products can be identified that were manufactured using the same production process. In the event of manufacturing errors, the batch number is important for identifying and recalling affected products. Batch traceability is required by law, especially for food and medical products, to ensure consumer safety.

The ERP software SAP Business One is ideally suited for effective batch management in medium-sized and small companies, as it ensures complete documentation of all goods movements and production processes. In the process, the synchronization of goods movements and the seamless tracking of batches facilitate management. The system is able to generate batches automatically from production orders and record all relevant information - starting with production and ending with delivery. Once a batch number has been assigned, all information on the individual batch can be viewed in SAP B1, including delivery date, serial number, expiration date and stock position.